Air Separator

Introduction

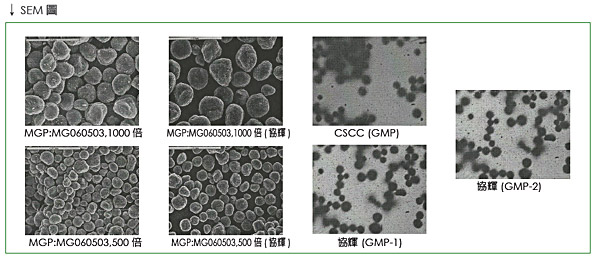

The basic factor to determine powder characteristics is particle size distribution. If particle size distribution

and utilization goal is suitable,the powder is stable with high added value. So,separation process is and important process for powder treatment industry.

Air Separator is the separator for the separation of micron powder and supermicron powder.

It is especially suitable to the powder which can not be separated by conventional

screen. It has high effi ciency. So,it is a very good separator all over the world.

The basic factor to determine powder characteristics is particle size distribution. If particle size distribution

and utilization goal is suitable,the powder is stable with high added value. So,separation process is and important process for powder treatment industry.

Air Separator is the separator for the separation of micron powder and supermicron powder.

It is especially suitable to the powder which can not be separated by conventional screen. It has high effi ciency. So,it is a very good separator all over the world.

Air Separator is the separator for the separation of micron powder and supermicron powder.

It is especially suitable to the powder which can not be separated by conventional screen. It has high effi ciency. So,it is a very good separator all over the world.